In today’s rapidly evolving global market, businesses across all industries must be agile and efficient in their production, delivery, and other operations. To address this challenge, modern-day enterprises are shifting to digitalising processes, particularly by leveraging the Internet of Things (IoT) for industrial applications. An important aspect of digitalisation is optimizing supply chain management and logistics to ensure stable production and meet customer demands. The integration of IoT in supply chain management is a favourable practice which allows businesses to effectively fulfil their requirements and achieve their goals.

Further, we will understand the significance of IoT in managing logistics and supply chain operations. The IoT solutions and use cases can impact the overall relationship of businesses with customers.

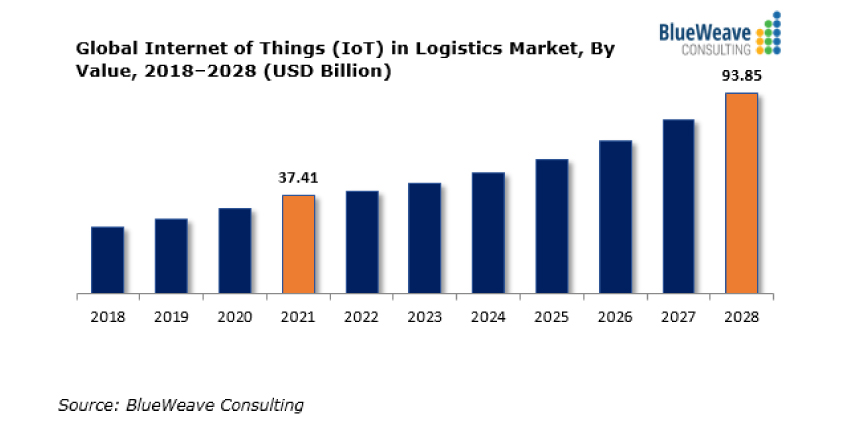

According to Bluewave Consulting, Global IoT in the logistics market size is expected to grow at a CAGR of 14.0%, reaching a value of USD 93.85 billion by 2028.

How IoT is Used in Supply Chain Management?

The role of IoT in supply chain management and its further impact on logistics and production is expansive. The IoT comprises various assets and devices that are connected to the internet, such as GPS trackers, sensors that measure humidity and temperature, and image translators. IoT in logistics and supply chain facilitates the collection of real-time data on the condition of stored or transported products which further enables monitoring of their status throughout the shipping and storage process.

Moreover, IoT sensors in the supply chain allow the processing of collected data and quick response to any anomalies that could damage the goods or disrupt production or logistics procedures. Such continuous monitoring and analysis by IoT in supply chain management guarantee seamless end-to-end manufacturing and delivery, with minimal delays.

IoT Solutions for Supply Chain Management

Businesses which invest time and resources in exploring and adopting practical IoT applications are the ones which can leverage the benefits of this technology. The shift away from traditional “offline” methods is already underway, as apparent by the growing adoption of IoT.

Given the current pace of technological advancement and the anticipated continuous growth, outdated structures and methods are becoming increasingly negatively impacting industrial operations.

Now let’s take a look at the current usage of IoT solutions for supply chain management and logistics.

-

Facility Condition Monitoring

IoT can monitor environmental conditions as it can save time and resources. Monitoring conditions throughout the supply chain has always been important. For instance, if a product needs to store in a warehouse for a long time, it’s essential to know the temperature inside the facility. Usually, the monitoring of products within the warehouse is a manual and time-intensive process as it requires visiting various devices distributed throughout the building to download data.

Now, IoT has transformed this process. With IoT, the latest devices are connected using low-powered wide-area networks (LPWANs) which enable real-time transmission of information to a central platform and the customer. Furthermore, IoT helps in configuring the system to automatically alert the customer if there are any variations in temperature or humidity.

At a strategic level, this data can be used to assess general warehouse conditions and impact future decisions regarding maintenance.

-

Cold Chain Monitoring

The Covid-19 pandemic has tested the efficacy of IoT in providing strategic solutions, and fortunately, it has emerged as a reliable technology. The best examples of pandemic-based acceleration in business are the rushed development of vaccines, and logistics companies faced the challenge of delivering them quickly and safely worldwide. Hence, it required end-to-end visibility on vaccine cold chains.

Similar to monitoring facility conditions, cold chain monitoring involves the use of connected devices to track each individual shipment and monitor its condition throughout the entire journey.

Apart from vaccines, numerous pharmaceutical products are sensitive to hot and humid conditions and must be transported and stored in temperature-controlled environments. Customers need to ensure that their products remain within a specific temperature range, even during inspections, loading, and unloading. IoT devices with the help of sensors collect and report conditions based on customer requirements, with the system alerting deviations outside the standard parameters.

This visibility ensures product stability and accurate reporting, such as audits. The increasing demand for lower temperature requirements in the manufacturing of drugs and treatments has led to a rise in the significance of IoT technology in the area of cold chain logistics.

-

Shipment Monitoring

The current monitoring of shipments is much more than tracking and tracing, as IoT technology is increasingly used to ensure security and prevent losses in logistics and supply chains. With vastly networked and online systems, users can observe a shipment’s journey from the moment it’s picked up to its final destination.

While GPS devices have been around for a while, recent advancements in size, battery life, and signal strength have made them ideal for quality control and loss prevention in the shipping of small packages. These devices come in various sizes and can detect factors like temperature, humidity, light, vibrations, and more.

For instance, by using a light detector, unwanted light inside a package can be detected, which suggests the package may have been tampered with or damaged. Since these devices are tiny enough that they can be discreetly placed inside packages, and if theft ever happens, such devices can assist in locating the stolen goods and help to solve the investigation.

-

Advanced Freight Stations

The operational methods of warehouses and distribution centres are undergoing a transformation with the help of IoT. Furthermore, in order to monitor environmental conditions, scanning technologies, both passive and active, are completely changing the way inventory is monitored and located.

Handheld scanners are gradually becoming obsolete and are being replaced by small vehicles that are equipped with sensors and RFID label readers, which travel through the aisles. Forklifts, with similar devices, can capture the location every time a pallet is moved. Moreover, an overhead dimensioning system can scan the size and shape of cargo when a forklift passes through the system, to ensure it fits the intended location.

IoT-enabled smart labels with RFID chips and their innovative applications are making the transformation of freight upgradation possible. The aim is to make the cargo smart and automate all aspects of the supply chain. With IoT, the cargo itself keeps the system updated by providing real-time visibility. The cases of lost freight will soon reduce to a great number.

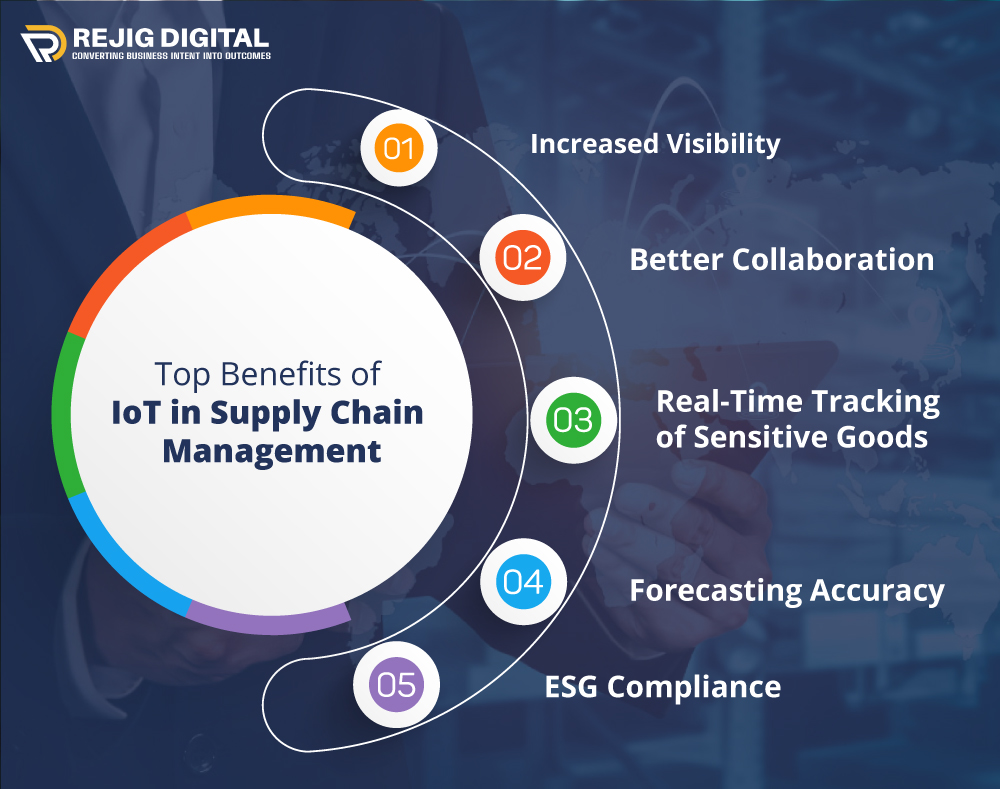

Top Benefits of IoT in Supply Chain Management

IoT is the best technology to transform the supply chain into fully connected networks. Here are the key benefits that IoT offers to supply chain management for streamlining the entire operations.

-

Increased Visibility

IoT allows supply chain managers to connect vehicles, equipment and devices for real-time status updates. As a result, IoT gives end-to-end supply chain visibility – from manufacturer to customer. With IoT, managers can get the precise location of the vehicle which allows them to make timely decisions regarding the movement of goods.

-

Better Collaboration

The IoT provides an overview of how business operations are affected by supply chains, which is particularly critical for intricate value chains that are frequently fragmented into isolated data repositories. IoT can break down such silos to facilitate the provision of valuable and timely information within supply chain teams, allowing them to collaborate and prevent potential problems.

-

Real-Time Tracking of Sensitive Goods

Accountability and transparency are important aspects of a supply chain, and real-time tracking facilitates both. IoT devices can monitor everything from the location of the shipment to its current temperature. As IoT in transportation solutions is growing, high-value items and sensitive goods can be easily tracked while moving from one location to another. Hence, customers have less chance of receiving spoiled items.

-

Forecasting Accuracy

IoT can eliminate human error in data collection as the technology collects abundant information automatically that too in real-time. As a result, demand forecasting can improve without human intervention. Managers can predict demand according to historical data and real-time data. For instance, stock levels can show the timing of orders or be utilised for order automation.

-

ESG Compliance

Nowadays, organisations are adopting best practices for health and safety and ESG issues. This ensures compliance with the ethical expectations of investors, customers and other stakeholders along with legislation. IoT sensors can quickly collect data which assists ESF compliance strategies and decision-making processes.

Wrapping Up

The role, usage, and benefits of IoT in supply chain management are limitless and go beyond human capacity. However, it is crucial for businesses to be aware of increased cybersecurity risks and implement effective security protocols. In order to prevent disruptions, it is essential to integrate IoT with robust security measures in current and future supply chains.

Rejig Digital is a leading provider of IoT solutions to help businesses streamline their operations and increase efficiency. Our expertise in IoT can help businesses achieve their operational goals and stay ahead in today’s digital age.