IoT, also known as the Internet of Things, it is a network that lets smart sensors, machines, and devices connect and talk with each other. These devices collect data and analyze it in real time, the data collected by smart sensors helps the organisations to make a smart decision. Industrial IoT platforms helps to analyze and learn from data that has been collected using sensors.

Industrial IoT platforms provide a base for sensors to work in a harmony. A thermometer functions as a basic temperature sensor, now Imagine multiple sensors attached to machinery that help to look after vibration, temperature, pressure, visuals, audio, and numerous other performance metrics. Industrial IoT platforms function in a similar way.

The Industrial IoT solutions help to predict potential breakdowns before they take place. Similar to a doctor keeping a constant eye on the health of the patient.

The primary quality that keeps IoT apart from other sensory metrics is its interconnectivity. The communication network enables the IoT devices to share data and helps to create a holistic picture while IoT provides a bird’s eye view of the entire ecosystem. The devices enabled by IoT have the ability to continuously transfer data and act like a digital brain that gathers, interprets, and presents actionable insights.

Industrial IoT platforms helps to receive real-time data by providing a window of insights. There are multiple facets in Industrial IoT solutions such as the health of machinery, total production, energy consumption, etc. that helps to predict breakdowns before they happen. This helps to reduce the total downfall and production loss preventing issues helps to avoid snowballs of the entire chain, leading to saving time, money, and energy.

It is possible to fine-tune operations with the help of IoT. It helps to eliminate wastage, allows the reallocation of resources, and boosts productivity. Data-driven decision-making helps to make smart decisions about production and resources, these insights give an edge over the competition and help to learn about the market and its trends in detail.

What is Industrial Internet of Things – IIoT

Industrial Internet of Things- IIoT is the new wave of the Internet and AI (Artificial Intelligence). These devices have their language of communication, and Industrial IoT platforms enables them to communicate internally in real time.

The sensors provide important information, exchanging data and performance metrics turning raw data into actionable data. The key factor that differentiates IIoT from other methods is the way the data is harnessed through the process for the specific industry.

The key components of Industrial IoT Platforms include:

Sensors

Sensors and devices collect the data throughout the process. Various parameters such as temperature, pressure, humidity, vibration, and more sensors can be used to manage and collect the data.

Connectivity

IIoT requires connectivity to transfer the data continuously. The connectivity can be provided through wired mediums or with wireless sensors such as Wi-Fi and Bluetooth.

Data Processing

IIoT devices are equipped with not only sensors but also systems that use advanced algorithms to analyze the received data. This data helps to extract insights, including patterns and predictions.

Cloud Computing

The data collected through sensors are saved into the cloud. The computing platforms are used to process the data and analyze it closely reducing the latency and enables faster responses.

Integration

Seamless integration among the existing system helps the supervisory control of the data acquisition and other operation technologies of the system.

IoT vs IIoT

Application Scope

The Internet of Things includes a very wide range of applications. The word “Things” has a very wide scope. The terms IoT (Internet of Things) and IIoT (Industrial Internet of Things) sound very similar. However, these two are very different and serve different agendas. From smartwatches to robotic equipment, IoT and IIoT have different purposes and use cases.

Realm of Internet of Things

A scenario where all the devices of a house are connected with one centralized platform. This removes the hassle of keeping a continuous eye on every appliance. Smart devices help to command appliances as per convenience. Lights get dimmed on voice command, fridge temperature rises, or decreases depending on the food storage requirement, and the fitness tracker measures every step and activity.

Data collected from the coffee maker can help to know which brew will have more strength and caffeine. Temperature sensors help run different electronic equipment such as air conditioners or heaters. The dystopian world is not just a fantasy anymore; it is slowly turning into a reality that people will embrace.

Dawn of Industrial IoT Platforms

Imagine a factory where the floor is being cleaned on its own. Machineries are communicating internally and making decisions. The symphony of machines working together using a suit of sensors increases the performance output. The Industrial IoT platforms enhances the vital performance metrics. The specialized machinery takes care of every requirement.

IIoT sensors are far more sophisticated than regular IoT sensors; they have a specialized deep memory embedded in sensors to constantly monitor the temperature, pressure, and vibrations of the operations. Once data is gathered, it is transferred using secured mediums to reliable servers that can process it and provide outcomes.

IoT vs IIoT – The Key Difference

Scope

IoT targets individual users and personal devices. Smartwatches, smart homes, wearable and connected devices. IIoT focuses on industrial settings and industries—manufacturing, energy, logistics, infrastructure, etc.

Security

IoT involves personal data, preferences, usage patterns of users, and the environment with basic protection measures. IIoT deals with critical industry operations. It requires production metrics, sensitive trade, business secrets, and machine health; a high-end security protocol secures it.

Technology

The average consumer leverages IoT for small-grade technologies such as smartphones, Wi-Fi, sensors, and affordability. IIoT demands industrial-grade devices, specialized sensors, and communication protocols. It also has powerful platforms for data analysis and visualization.

Benefits

Industrial IoT platforms enhances user performance by automating manual tasks and personalized experiences, while IIoT aims to automate the industrial process and focuses more on increasing productivity. Additionally, it involves avoiding any potential hazards.

IoT solutions are generally more affordable due to the vast number of consumers; IIoT involves a specialized skill set to create and add sensors that provide precise data. Both IoT and IIoT are power-connected devices that provide required data. It is crucial to choose the right tech for the specific need.

Technology behind Industrial IoT Platforms

AWS IoT Core

Amazon Web Services IoT Core stands as a leading cloud platform. It empowers businesses of every size to connect, manage, and secure all the devices on a larger scale. The use case of this technology can be seen in factories with sensors embedded in machines, sending critical data. AWS IoT Core acts as the central nervous system, collecting, analyzing, and delivering insights that transform operations.

Connectivity:

It acts as the bridge between your devices and the cloud, supporting diverse communication protocols like cellular, Wi-Fi, and industrial Ethernet. Think of it as a universal translator, ensuring seamless data flow from any type of device.

Management:

AWS IoT core acts as a control system for provisioning and registering devices, configuring security measures, and updating firmware. It serves as the control center for your entire IIoT infrastructure. It provides a centralized dashboard to manage all connected devices with ease.

Security:

Data security is paramount in industrial settings. AWS IoT Core boasts robust security features, including device authentication, encryption, and access control protocols, safeguarding critical information. It is a fortified vault, protecting sensitive data from unauthorized access.

Scalability:

AWS IoT Core readily scales to accommodate any type of need. It can handle millions of devices and messages simultaneously that ensures smooth operation as the IIoT infrastructure grows. It provides a platform that expands alongside ambitions without compromising performance.

Features of AWS IoT Core

Data ingestion and storage:

Services like Amazon Kinesis and Amazon S3 capture and store vast amounts of data generated by devices.

Analytics and machine learning:

Amazon SageMaker and Amazon Machine Learning help extract valuable insights from the data, enabling predictive maintenance, process optimization, and more.

Applications and solutions:

A marketplace of pre-built solutions and partner offerings cater to specific industry needs and use cases.

Benefits of using AWS IoT Core

Increased efficiency and productivity:

Gain real-time insights into operations, optimize processes, and minimize downtime.

Improved asset management:

Predict and prevent equipment failures through predictive maintenance, saving time and money.

Data-driven decision making:

Uncover hidden patterns and trends in the data, empowering informed decisions for better outcomes.

Enhanced safety and compliance:

Ensure adherence to industry regulations and safeguard critical data with robust security features.

Azure IoT

Azure IoT stands as a rock-solid force that is empowering businesses to unlock the potential of connected devices and transform their operations. When factory equipment is laced with sensors transmitting data, Azure IoT acts as a mentor, collecting, interpreting, and delivering insights that revolutionize productivity and efficiency.

Connectivity:

No matter how devices communicate, Azure IoT catches that language. It supports diverse protocols like cellular, Wi-Fi, and industrial Ethernet, ensuring seamless data flow. It works as a universal translator, breaking down communication barriers and connecting the entire IoT ecosystem.

Management:

By onboarding and registering devices to configure security and update firmware, Azure IoT provides a centralized platform. Azure provides a virtual control center where one can oversee all connected devices in one place.

Security:

Data security is paramount in the industrial realm. Azure IoT offers robust security features like device authentication, encryption, and access control mechanisms. It safeguards critical information from unauthorized access.

Scalability:

Azure IoT is built to scale seamlessly, it handles millions of devices and messages concurrently ensuring smooth operation as the industrial landscape expands.

Features of Azure IoT

Data and storage:

Azure Event Hubs and Azure Data Lake Store capture and store the vast amounts of data generated by IoT devices.

Analytics and Machine Learning:

Services like Azure Machine Learning and Azure Databricks empower to extract meaningful insights from data, enabling predictive maintenance, process optimization, and more.

Applications:

A marketplace of pre-built solutions and partner offerings cater to specific industry needs and use cases, accelerating your IIoT journey.

Benefits of Azure IoT:

Increased efficiency and productivity:

Gain real-time insights into the operations, optimize processes, minimize downtime, and maximize output.

Improved asset management:

Predict and prevent equipment failures with predictive maintenance, saving time and money on repairs and replacements.

Data-driven decision making:

Uncover hidden patterns and trends in data, empowering informed decisions for better business outcomes.

Enhanced safety and compliance:

Ensure adherence to industry regulations and safeguard critical data with robust security features.

IBM Maximo

IBM Maximo is an Enterprise Asset Management (EAM) platform. It goes beyond simply tracking physical assets; it empowers to optimize performance, extend life cycles, and ultimately maximize return on investment.

Asset Register:

It creates a comprehensive record of all physical assets, including details like location, specifications, and maintenance history.

Work Order Management:

Planned, scheduled, and managed work orders for maintenance, repairs, and inspections, ensuring efficient resource allocation and timely completion.

Inventory Management:

Track and manage spare parts, materials, and tools, optimizing inventory levels and reducing costs.

Reporting and Analytics:

Gain valuable insights into asset performance, maintenance effectiveness, and overall operational health through extensive reporting and analytics capabilities.

Features of IBM Maximo

Industry-specific solutions:

Tailored versions for various industries (e.g., utilities, oil & gas, transportation) cater to specific needs and regulatory requirements.

Predictive Maintenance:

AI and machine learning to predict equipment failures before they occur minimizes the downtime and costs.

Mobile capabilities:

Access Maximo and manage assets as they go through mobile apps, improving field technician efficiency and responsiveness.

Integration with other platforms:

Connects seamlessly with other IBM solutions and third-party applications.

Benefits of IBM Maximo

Reduced downtime:

Proactive maintenance with Maximo helps prevent unexpected equipment failures, minimizing downtime and associated costs.

Improved asset life cycle:

Extend the lifespan of your assets through proper maintenance and optimization, maximizing return on investment.

Enhanced efficiency:

Streamline maintenance processes, optimize resource allocation, and gain real-time visibility into asset performance.

Data-driven decision-making:

Leverage robust reporting and analytics to make informed decisions about asset investments maintaining strategies and overall operational improvements.

Advantages of Industrial IoT Platforms

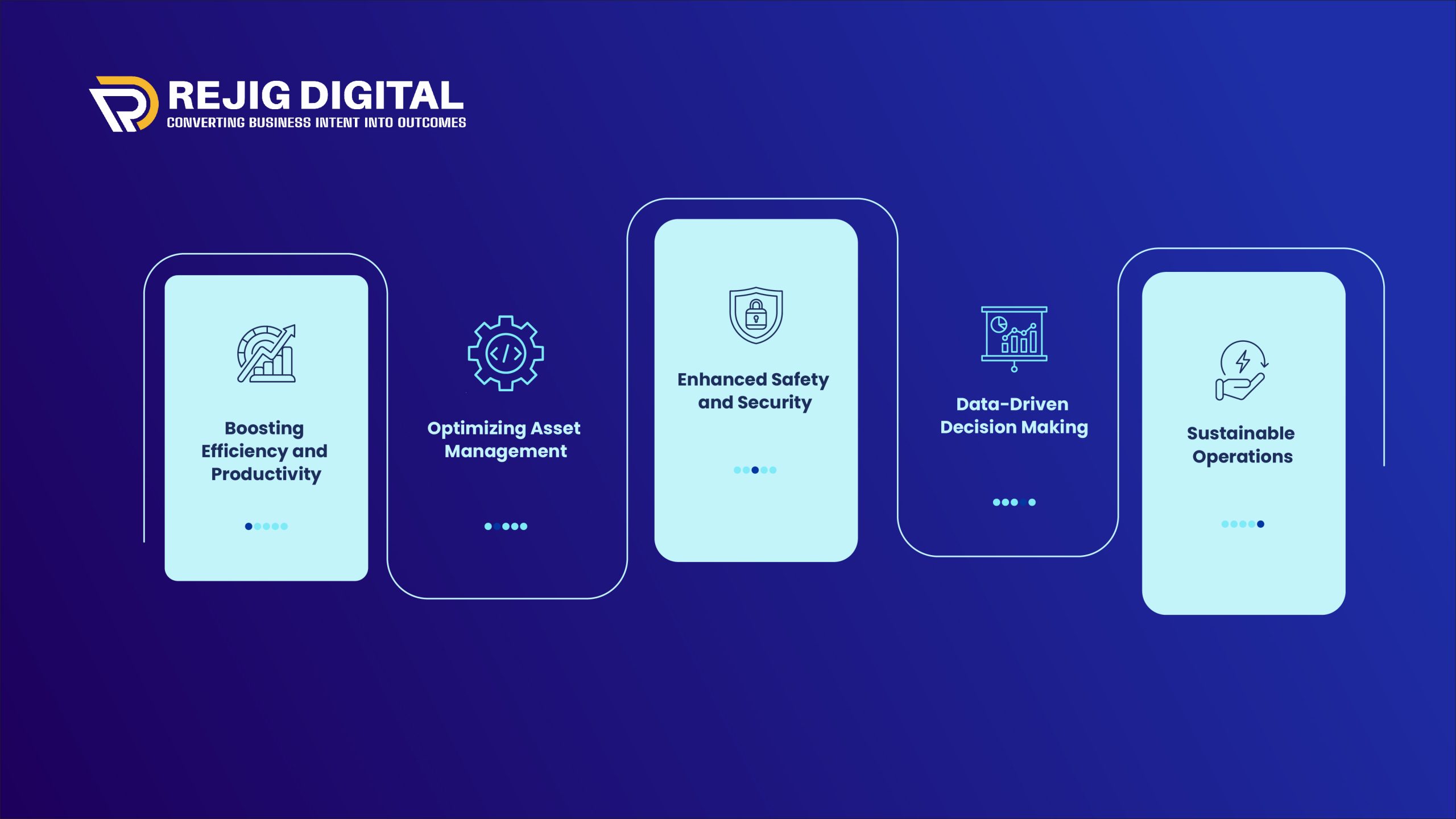

Boosting Efficiency and Productivity with Industrial IoT Platforms:

IIoT provides a live dashboard displaying performance metrics across the entire operation. With this real-time visibility, one can identify bottlenecks instantly. One does not have to wait for reports, and decisions can be made in real time.

Optimizing Asset Management:

IIoT platforms utilze the wear and tear platforms for reactive repairs and proactive mauntenance. IIoT’s predictive capabilities translate to fewer breakdowns, less emergency maintenance, and significant cost savings.

Enhanced Safety and Security:

The sensors can detect potential hazards like gas leaks or overheating equipment in real time. IIoT allows immediate alerts and preventive measures, safeguarding workers and preventing accidents. In a world of connected devices, cybersecurity is crucial. IIoT employs robust security measures like encryption and access control.

Data-Driven Decision Making with Industrial IoT Platforms:

IIoT analyzes data, uncovering trends and identifying areas for improvement. It provides recommendations for informed decision-making. Data-driven strategies guide your path to success. IIoT helps to combine data with human expertise, fostering innovation in process optimization, product development, and service offerings.

Data paints a transparent picture of operations. With IIoT, everyone has access to the same information, promoting accountability at all levels and driving organizational improvements.

Sustainable Operations:

Real-time data enables one to monitor and optimize energy consumption across the entire operation. This translates to reduced energy use, lower costs, and a smaller carbon footprint. Eliminate waste in your processes with the help of IIoT-driven insights. This could be anything from minimizing material waste to optimizing energy usage, contributing to a more sustainable manufacturing environment.

Application of Industrial IoT Platforms Across Industries

Devices and Sensors

Sensors:

Detect various physical details like temperature, pressure, vibration, and motion from equipment and processes.

Smart meters:

Track energy consumption, enabling resource optimization and cost reduction.

Connected machines:

Collect data on performance, usage, and potential issues, facilitating predictive maintenance and process improvement.

Communication Networks

Industrial Ethernet:

Reliable and secure wired network for high-speed data transmission within factories and facilities.

Network:

Enable data transmission from remote locations and mobile assets, offering flexibility and wider coverage.

Edge Computing

Real-time decision-making:

Analyze data and generate insights closer to devices, facilitating faster reactions and optimizations.

Reduced network bandwidth usage:

Pre-process data before sending it to the cloud, minimizing bandwidth consumption and costs.

Improved security and privacy:

Sensitive data stays closer to the source, enhancing security and privacy control.

Cloud Platforms

Data storage:

Store vast amounts of data from various sources securely and efficiently.

Data analytics and machine learning:

Analyze data to extract insights, identify trends, and predict future outcomes.

Application development:

Build and deploy custom applications or integrate with existing systems.

Security

Device authentication:

Ensure only authorized devices and users can access the network and data.

Data encryption:

Protect data in transit and at rest from unauthorized access and cyberattacks.

Network security:

Implement firewalls and intrusion detection systems to safeguard the entire IIoT ecosystem.

The Future is Now: Embrace the IIoT Revolution

The Industrial Internet of Things (IIoT) is no longer a futuristic vision; it has become a reality now, with immense potential to transform industrial operations. From boosting efficiency and optimizing assets, driving data-driven decisions, and fostering sustainable practices, IIoT empowers to thrive in the competitive landscape.

This journey doesn’t begin and end with technology. It requires a cultural shift towards embracing data, fostering innovation, and investing in the right talent. With careful planning, strategic implementation, and a commitment to continuous improvement, IIoT can unlock a future of optimized operations, sustainable practices, and unrivaled efficiency.

Keep the IIoT wave from passing you by. Start exploring the possibilities, identify your specific needs, and take the first step toward a data-driven, connected, and future-proofed industrial world.