In today’s fast-paced, data-driven business environment, optimising warehouse operations is crucial for companies seeking to gain a competitive edge. With the rise of IoT in smart warehouses, businesses are access to abundant real-time data that is beneficial in optimising inventory management, streamlining workflows, and reducing costs.

According to Grand View Research, IoT in the Warehouse Management market is expected to reach USD 19.06 billion by 2025.

Further, we’ll explore the latest IoT applications for smart warehouse management, and how IoT-enabled solutions can help in improving efficiency, productivity, and customer satisfaction.

IoT-powered Smart Warehouse: A Brief Introduction

An IoT-powered smart warehouse is an operational area that integrates Internet of Things (IoT) devices, sensors, and systems to improve its overall efficiency and productivity. IoT-enabled devices and sensors are used to collect and transmit data on warehouse operations, such as inventory levels, equipment performance, and worker productivity. This data is then analysed in real-time to optimise processes, reduce costs, and improve overall warehouse performance. Overall, IoT provides a smart Warehouse Management System.

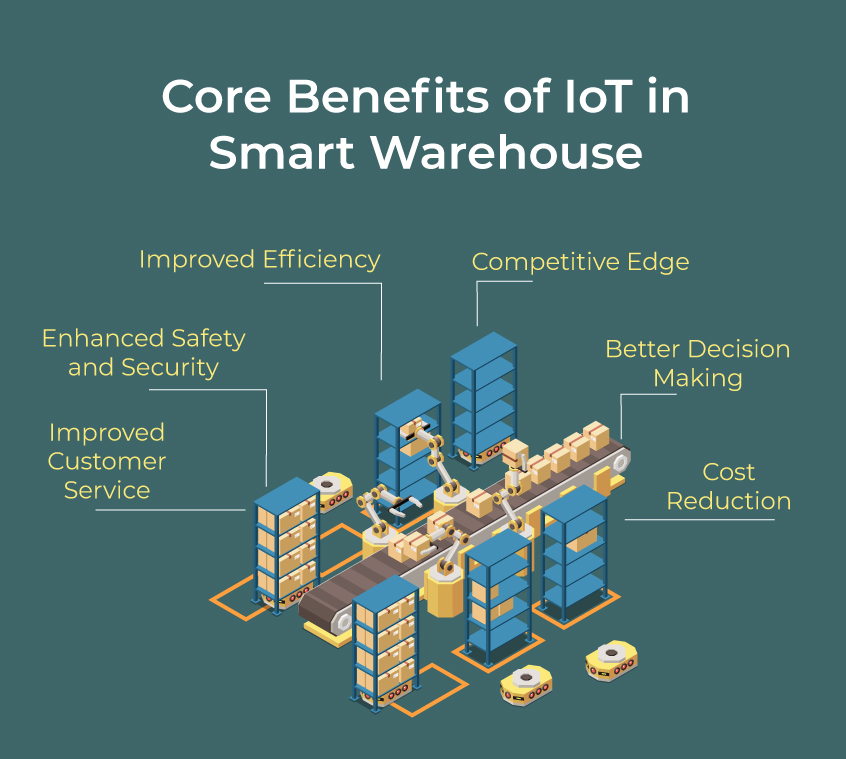

Some of the core benefits of IoT in smart warehouses.

-

Improved Efficiency:

The data from IoT sensors and devices is crucial to identify inefficiencies and optimising processes, which results in improved efficiency and productivity.

-

Enhanced Safety and Security:

IoT sensors can monitor warehouse conditions, such as temperature, humidity, and lighting, to ensure optimal working conditions for employees. Moreover, IoT-enabled security systems can monitor the warehouse for potential breaches and alert the concerned personnel to prevent theft and other security risks.

-

Improved Customer Service:

IoT technology can provide customers with real-time information on their orders, such as tracking information and estimated delivery times. It further improves customer satisfaction and increases loyalty.

-

Competitive Edge:

Smart warehouses with IoT can gain a competitive advantage by delivering products faster, more efficiently, and at a lower cost than their competitors.

-

Better Decision Making:

Managers can make more informed decisions by collecting and analysing real-time data on warehouse operations which optimizes processes, reduce costs, and improve overall warehouse performance.

-

Cost Reduction:

The optimisation of processes facilitates reduced costs associated with labour, inventory management, and maintenance. Moreover, IoT-based predictive maintenance can also prevent costly equipment breakdowns and reduce downtime.

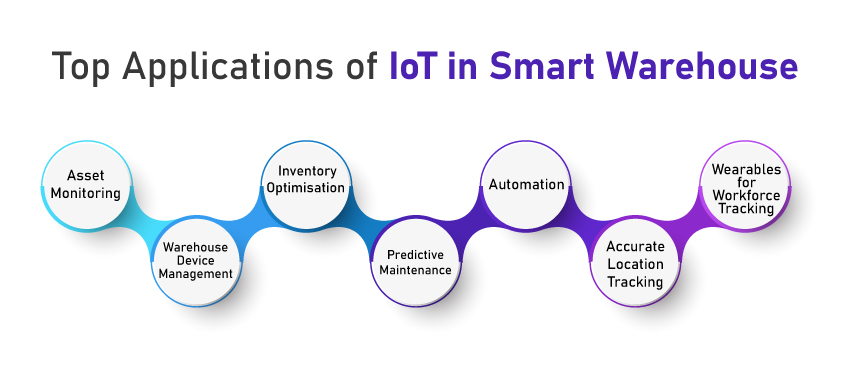

Top Applications of IoT in Smart Warehouse

Warehouses deal with many challenges to improve efficiency and productivity. In order to combat these challenges, industry experts use IoT in supply chain management, with sensors that collect data from different points of operation. The entire analysis of data offers effective, productive, and efficient ways of running the business.

Here are some key applications of IoT for warehouse management:

-

Asset Monitoring

IoT management of warehouses supports businesses with transportation data, location, packing, and shipment in real time. Businesses can ensure that no asset loses track owing to instant updates that are received by users in case of any irregularities. All these aspects are also applicable to human employees. Companies can follow the position of personnel in real time and handle the assigned duties and functions accordingly within warehouses.

-

Warehouse Device Management

Smart warehouse assets such as shelf sensors enable one to find equipment and manage inventory efficiently. Moreover, it’s easy to take instant preventative steps for sensor-embedded assets in case of emergencies. For instance, if an item is out of stock, managers will get a notification instantly so they can take an informed decision. Accurate asset data, location, condition, and many more information help in efficient warehouse management.

-

Inventory Optimisation

IoT-based data analytics supports the development of future business plans. Since it monitors every action and processes data, companies can understand what is required and what doesn’t work with the operation. Thereafter, companies can plan and schedule inventory stock. It further helps in optimising warehouse space and reduces the time required for locating and collecting your stock items.

-

Predictive Maintenance

IoT sensors can monitor machines and their working conditions. Integrating operational equipment data with machine learning algorithms prevents the unwanted breakdown of assets. As a result, warehouse managers can maintain the quality of production and reduce maintenance costs and downtime of machines.

-

Automation

The IoT is capable of verifying shipping and service tracking. Adopting IoT can reduce the long hours that inventory managers or other personnel spent on manual monitoring and reporting. As IoT can monitor and collect data with its sensor, the information is recorded for large warehouses. It drives automated tracking of assets and their condition which minimises human errors that further save a substantial amount of time.

-

Accurate Location Tracking

As the warehouse usually contains a wide variety of goods, inventory and personnel, it is crucial to synchronise all these aspects to achieve work cooperation. This is where IoT technology comes into play as it offers precise location tracking that enables managers to have proper control over assets and the workforce.

-

Wearables for Workforce Tracking

Wearables include IoT devices attached to the uniforms of personnel working in warehouses. It helps in tracking the movements of employees. Wearables have the following functions:

- Check-in and check-out: There is a high possibility that employees can manipulate their attendance records with paper-based check-ins and check-outs. Hence, employees with IoT-powered wearables can drive transparency with automated attendance.

- Detects real-time employee movements: Wearables with their sensors can collect information about the activities and locations of employees. It allows managers to get aware of whether the employees are performing their job and which workers need additional support.

- Automated work completion report of employees: Wearables with the capability of tracking movement allow employees to automatically complete their work orders. Workers do not need to manually report to the managers as it takes a long time.

- Assigning employees for MHE: Warehouse operations always include Material handling equipment (MHE). Wearables allow managers to assign MHE to the nearest employees instead of spending time making a decision.

The Ending Note

As we have seen, the applications and benefits of IoT in smart warehouse management are numerous, from increased efficiency and productivity to enhanced visibility and control over inventory and assets. By adopting IoT-based applications, companies can stay ahead in the competitive market and thrive in the rapidly-evolving digital age through real-time data and insights.

Rejig Digital is a leading provider of Internet of Things solutions by driving innovations in warehousing operations. IoT in smart warehouses can take help you achieve your goals and succeed in the competitive landscape of today’s business world.