Innovative technologies for the chemical industry make it to efficiently move forward in a changing world. Incorporating IoT in chemical industry leads the sector towards efficiency to create better results. The increasing adoption of automated industrial processes grows the demand for IoT in the chemical sector.

The IoT technology within the Chemical domain is positively impacting the process flows, work formation, and functionalities. Furthermore, it also monitors the employees’ location, which maintains their safety in disaster-prone areas.

According to Markets and Markets, the global IoT market in the chemical industry is expected to be valued at USD 77.9 billion, registering a CAGR of 9.7%, by the year 2024.

How IoT Helps Chemical Industry to Move Forward?

The chemical sector is constantly making improvements in terms of safety, efficiency, and other aspects which give a boost to the bottom lines. Many companies in the chemical industry is gradually realizing that adopting IoT technology is the best way to meet various business goals.

-

Enhance Plant Activity with Predictive Maintenance

Operations in a chemical plant require the management of even small details to yield the desired results. If companies are haphazard with some parts of their processes, it can result in catastrophes. This is where IoT comes into play as its automated treatment takes care of various requirements.

The IoT-based monitoring and management keep equipment running without compromising production output. It also ensures that machine breakdown doesn’t occur during peak operational hours. Embedding IoT sensors in machines enable the receiving of alerts about sudden obsoletion or cleaning to match the need of chemical plant need. Hence, human error becomes less of an obstruction in task optimisation within chemical plants.

In addition, IoT sensors can also program lighting. Chemical cleaning often requires a blacklight that asses the contaminates in the equipment. IoT initiates the system of “smart blacklights” by syncing when they turn on until the end of the cleaning cycle. It improves the cleaning efficiency of machines.

With IoT on the floor, plant employees can maintain the equipment in ways that prevent process disturbances that may result in ceased operations. As chemicals can create hazards to humans, manual inspection of the tank is unfeasible for plant employees. Here, IoT can monitor the tank and deliver real-time information to workers to make a preventative maintenance analysis. This method can save long labor hours in inspection time.

-

Enabling Chemical Plants to Scale-Up Production

IoT technology plays an important role when chemical plants need to scale up their production capabilities. Increasing production runs the risk of compromising quality control, especially if facilities try to increase output at unsustainable levels.

But, IoT technology can reduce possible problems by automating various parts of the process and providing plant workers with data that could indicate many inefficiencies.

With IoT-generated data, chemical industry leaders can recognize the demands of the market. It helps in chemical process control which enables more profitability while having a positive impact on the industry as a whole in the country’s economy.

Hence, IoT can help chemical entrepreneurs to retain an emphasis on quality while significantly increasing production.

-

Promotes Continual Process Improvements

Chemical plants usually have a high number of control loops, and each one relates to some aspects of a broader process. For instance, one control loop maintains a proper temperature while another monitors the flow level of a substance moving through a pipe.

In such cases, it is important to keep the control loops to the best of their capabilities. Addressing the issues of the control loop at right time maintains the correct functionality of individual components. Plant operators repair or changes those parts of machines as a necessity for excellent chemical process control.

IoT equipment can recognize bottlenecks and inefficiencies in a complete process while also constantly optimising the plant’s operations. The data offered by IoT equipment can help chemical plants update their assets, and run the functions of control loops effectively

The collected data by IoT sensors give managers detailed visibility into the operations of a plant’s operations. IoT made it possible to understand process shortcomings and take a step to improve them. The informed decisions which are taken after analysing data help companies enhance day-to-day operations which makes them prepared for regulatory inspections.

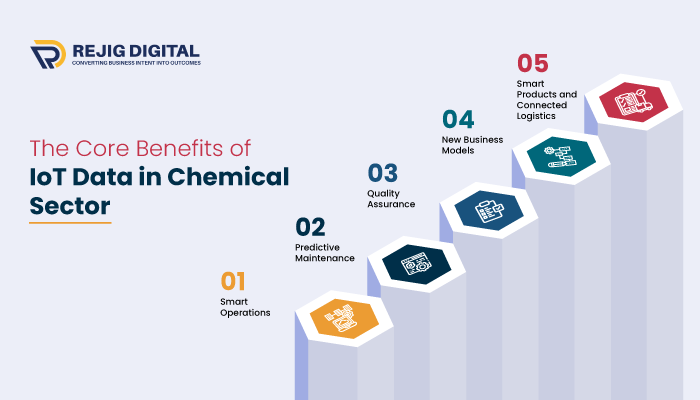

The Core Benefits of IoT Data in Chemical Sector

The chemical industry has intense competition, hence, it would be a great idea to fully explore the benefits of IoT data. Using various algorithms and applications of IoT in chemical industry, expose industry professionals to massive data which can further turn into actionable insights for efficiency and improvements in operations.

-

Smart Operations

Chemical organisations can generate a large volume of data during manufacturing. However, they utilize only a small amount to improve decision-making and add value. On the contrary, enterprises can blend all the data collected by IoT sensors analyse it in real-time, and use results for informed decision-making, improving operational, safety, and environmental performance.

-

Predictive Maintenance

Equipment such as chemical reactors can turn into a smarter asset with embedded software and analytics that can diagnose their health. Machines send signals about their status and performance that show the possible malfunctions and maintenance requirements. It is further enhanced with 3D asset visualization known as augmented reality, which improves maintenance and keeps machinery in the best form to prevent disturbance in ongoing operations.

-

Quality Assurance

As IoT facilitates the analysis of large quantities of data, it also contributes to the improvement of quality assurance and processes. Chemical companies that still lag behind in adopting IoT, mostly focus on the last 30 batches of materials to manage process quality and controllability. Whereas, companies with the facility of IoT can analyse the high number of batch results and use the data set to change operating conditions and improve quality.

-

New Business Models

The stakeholders of the chemical industry need a secure, big data-enabled platform for accessing and sharing data to support favorable decision-making. Sensors capturing and transmitting information such as local weather data, GPS data, or properties of certain chemicals and their effect and demands play a pivotal role in the success of innovative business models.

-

Smart Products and Connected Logistics

The chemical sector is complex and heavily regulated, hence, it is crucial to have an integrated supply chain. Data from sensors embedded in the product packaging or transportation assets can help to track and trace the location, condition, and authenticity of products. For instance, products send alerts when temperature or moisture levels increase or decrease from acceptable ranges when products are on their way to the final destination.

Ending Note

Chemical industry solutions of IoT can create new value for customers with its insights into operations and market demands. Chemical companies can improve the speed of product delivery in the market. Moreover, they can offer customers more options for their products or flexibility in production. Overall, IoT can help the chemical industry pace up with changing times and meet the needs of shareholders and customers.

Rejig Digital is a renowned entity that provides Industrial IoT solution-Arete-to the chemical sector. Our expertise in IoT in chemical industry enhances operational capabilities and successfully overcomes many challenges of this industry.