Digital transformation presents new ways of working, discovering new opportunities, and driving enterprises to a new level. Talking about the chemical sector, these companies can also leverage the benefits of new technologies and the fourth industrial revolution (Industry 4.0) to eliminate downtime and improve profitability. In other words, digital transformation solutions can be a game-changer for the thriving chemical sector.

However, to reap the benefits of digital transformation in the chemical industry, companies need a robust internal framework based on the factors like-

- Analyzing the current situation

- Identifying the desired outcome

- Mapping the steps and methods

- Creating progress KPIs

- Contingency and risk mitigation plans

Expectations of Chemical Companies from Digital Transformation Solutions

Digital transformation has started offering multiple benefits to companies irrespective of their scales and business models. Emerging technologies like IoT, digital twins, and AI can be integrated into digital transformation software to get the desired outcome. What’s more, companies can easily take the advantage of an innovative approach and drive growth through digital transformation.

Nowadays, the CTOs, CEOs, and visionary leaders of every industry sector are expecting digital transformation solutions and IIoT to fetch even better outcomes. Here, the chemical industry is also no exception!

A GPCA survey reveals that 63% of the chemical company CEOs have kept digital transformation as the primary element of strategy making for the next two years. As a result, they are also planning to invest 5% of their annual revenue towards completing the inclusion of Internet of Things Industry 4.0 systems and related technologies into their system.

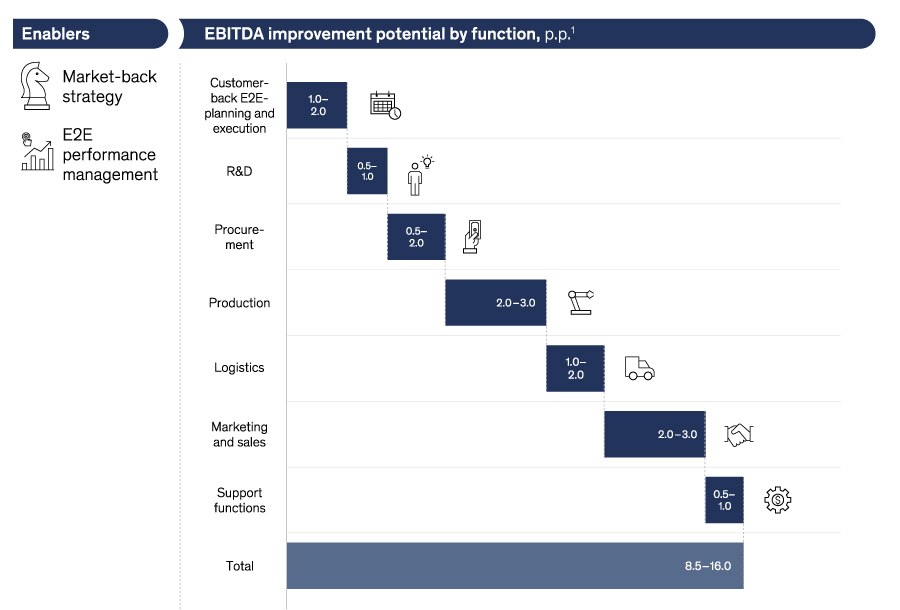

In terms of revenue generation and cost savings, a McKinsey study finds that an end-to-end implementation of digital technologies can create an overarching impact. Specifically, it has been known to lead to 8.5% to 16% EBITDA improvement.

Source: McKinsey

However, companies need to create a sweeping implementation plan to enable maximum value capture from these methodologies. Also, they must focus on the digital transformation strategy based on trends and insights in the chemical industry. Let’s dig deep into the top trends of Chemical 4.0 that can determine the direction of digital transformation.

Chemical 4.0 Trends and Insights

1. Harnessing the Power of Data

Data is the cornerstone of every industrial digital transformation process. Every equipment and firmware installed to support the digital transformation generates data.

Chemical companies must harness data and build models for its implementation in every system. From asset performance, and maintenance, to product improvisation, discovery, understanding the customers, etc. data can help improve the outcome.

Systems like digital reliability platforms (DRP) can be used to predict equipment health and set up predictive maintenance systems.

2. Production Optimization

When data and its models are implemented, production optimization is observed firsthand. Where companies, based on the insights provided, build iterative supply chains, and production processes, while automating the repetitive tasks, they observe better performance.

Moreover, with benefits like remote monitoring, improved equipment efficiency, predictive maintenance, pinpoint issues, etc., chemical plants will get better integration of processes on a granular level.

3. Predictive Maintenance and Artificial Intelligence

The way chemical companies can leverage predictive maintenance deserves a special mention. With the help of advanced technologies like artificial intelligence and machine learning, companies can;

- Spot anomalies

- Detect fouling

- Detect part failures or probable failures

It can help predict or detect all the issues that can either decrease the machine’s efficiency or its ability to produce the desired product. Because it’s an AI and ML-based system, it can go deeper into the machine’s system than a human being and identify issues at the molecular level.

Also Read : Maintenance 4.0: Scale the reliability, performance, and safety of your assets

Companies that are using remote asset management systems based on predictive maintenance can get the benefits like

- Reduced downtime

- Less tool failure

- Less maintenance demands

- Early detection of quality-related issues

- Improved ERP utilization

- Minimize scrap

- Predict workforce demands

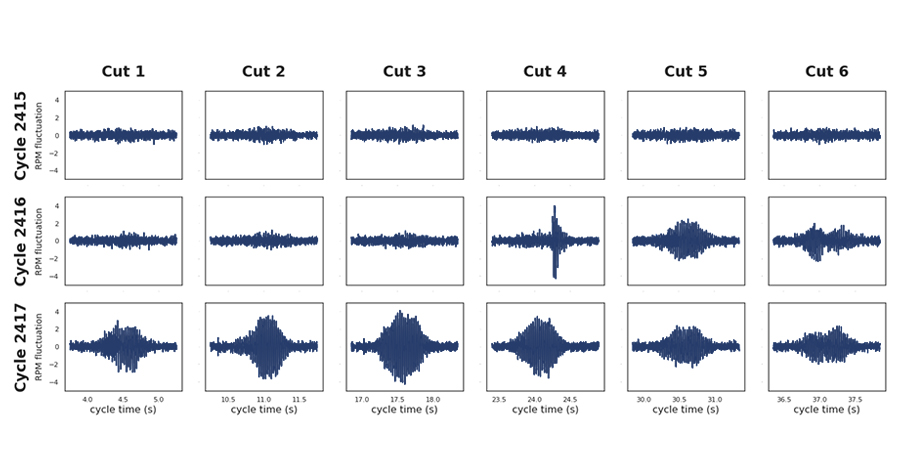

Source: Machine Metrics

The image above shows how many parts could be made with the machine until the result can be tool failure due to increased load. With such information, machine use can be optimized to ensure maximum output without risking downtime and equipment failure.

4. Cost Savings

Digital transformation in the chemical industry is also used to save costs and enhance reliability. The cost-saving part comes from detecting equipment failure and improving the entire supply chain.

Chemical companies are using centralized data collection hubs to analyze, visualize, and interpret data leading to early maintenance of the machines. Not only this, but they are also using the data to find better ways of producing the same product with less resource utilization and in less time.

The digital technologies also keep the employees updated about the real-time status of machines, processes, and products. In a way, employees can make better decisions based on accurate information.

There are solutions helping every level of employee access precise and accurate information.

5. Remote Assistance and Operations

During the pandemic, almost every company had to make arrangements for remote working environments. This led them to evaluate their existing situation and infrastructure. Remote assistance and monitoring of assets can be based on analyzing the company’s existing capabilities and future requirements.

In the current scenario, the C-suite executives have already built systems to sustain operations in the wake of pandemic-like situations. And for this, they are heavily relying on digital transformation technologies and systems to ensure remote visibility, diagnostics, and ensure timely maintenance of machines.

Hence, digital transformation in chemical industry is well on its way to establishing a hybrid work environment.

Conclusion

Digital transformation and its technologies can help companies in three ways;

- Ensure better growth and innovation

- Improve performance and build cost optimization techniques

- Ensure sustainability

While these three are the pillars of every company’s growth structure, achieving them requires the utilization of the right technologies. Effective usage of these technologies can lead to operational excellence. That is why in the next three years, 2/3rd of the chemical companies are expecting to see revolutionary changes.

Do you want to become the pioneers of change in the chemical industry? If yes, you must look at effective digital transformation in chemical industry systems to help you achieve the desired results and drive growth.