Optimisation plays a vital role in the survival and prosperity of the manufacturing industry. With recent technological advancements, numerous businesses are evaluating ways to leverage IoT-enabled smart manufacturing which leads to enhanced productivity and output. To meet the demands of fast delivery and superior quality in today’s business landscape, many enterprises have adopted connected technology to transform their warehouses into smarter facilities to further increase efficiency and stay competitive.

According to Markets and Markets, the global IoT market is expected to increase in revenue by around $87.9 Billion with a CAGR of 11.9% by the end of 2026.

Evolution of IoT and Industry 4.0

The rapid advancement of Industry 4.0 can be attributed to the Internet of Things (IoT), as it enables seamless connectivity among various components within a shared network. This connectivity facilitates extensive automation which reduces the requirement for extensive human involvement. Decision-making processes can be easy by monitoring real-time data, while predictive capabilities mitigate potential future risks. Furthermore, asset management is optimised to ensure long-term operational efficiency.

The key stages in the evolution of IoT and Industry 4.0 include:

- Establishing connectivity among devices and systems

- Extracting valuable insights from the collected data

- Enhancing efficiency and effectiveness of operations and processes

- Fostering innovation to drive continuous improvement

What is SMART MANUFACTURING?

Smart manufacturing involves the utilisation of IoT technology and automation in operations which can constantly enhance productivity. Leveraging IoT for accurate monitoring of assets ensures worker safety, boosts productivity, and enhances security within your production environment. By integrating IoT and other emerging technologies, businesses can unlock the full range of benefits that arise from converting their manufacturing warehousing facilities into smart spaces.

Currently, the manufacturing industry is going through a significant digital transformation. It has witnessed the emergence of new technologies and their applications, such as artificial intelligence, cloud computing, IoT connectivity, predictive analytics, quantum computing, advanced additive manufacturing technologies like 3D printing, cyber-physical systems, and many more. These technologies have collectively initiated the advent of Industry 4.0.

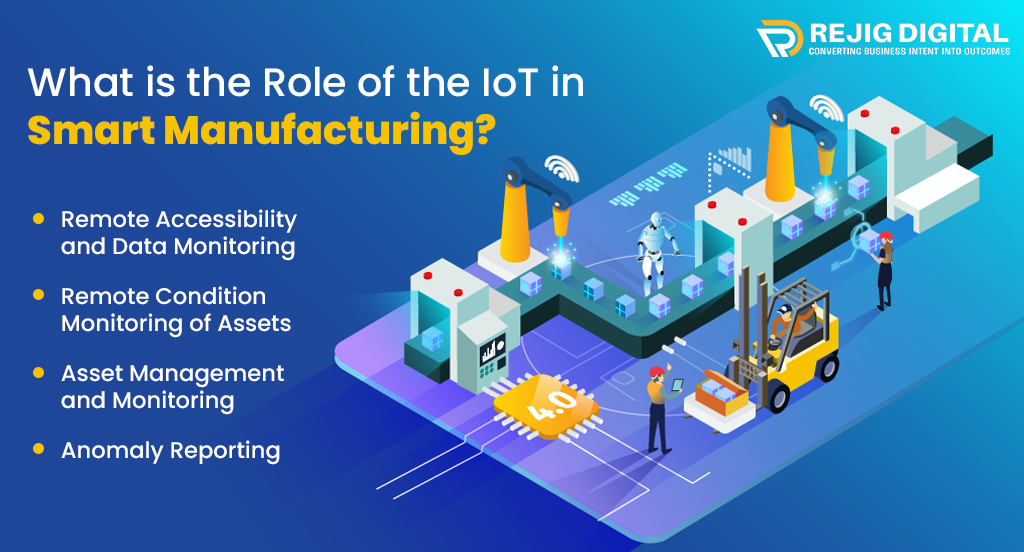

What is the Role of the IoT in Smart Manufacturing?

IoT plays a huge role in smart manufacturing as it is efficiently utilised in the production process for a rapid and favourable outcome. IoT-enabled smart manufacturing entails the implementation of its framework within a manufacturing setting, where it creates a smart manufacturing ecosystem.

This ecosystem connects machines, devices, and processes through data communication systems which generate valuable data for production processes. Moreover, the data generated by IoT provides insights into previously undiscovered activities within the production process. By analysing this data, IoT enables the generation of useful insights which was earlier not possible with manual operations.

Referred to as enablers, IoT-enabled smart manufacturing can enhance productivity, reduces downtime, improve efficiency, and increase overall profits. The main objective of IoT in manufacturing industry is to accelerate various aspects of manufacturing operations which enables manufacturers to achieve their goals more effectively.

-

Remote Accessibility and Data Monitoring

IoT allows production managers to have the ability to monitor operations and collect information remotely from any location or time of day. By utilising IoT-enabled devices, managers can oversee the production process and control operations from a distance. This remote access to data saves time and effort, as managers can stay informed without needing to be physically present on-site.

-

Remote Condition Monitoring of Assets

IoT devices play a crucial role in providing remote condition monitoring and control within the manufacturing industry. Production managers can remotely monitor the condition of assets which ensures optimal performance and reduces downtime. If any issues arise, IoT devices alert the production manager which enables them to make necessary adjustments rapidly.

-

Asset Management and Monitoring

IoT-enabled smart manufacturing facilitates accurate monitoring of assets and enhances inventory management. It enables effective control of asset quality, detects issues of theft, and optimises logistics for efficient asset management. With real-time monitoring of inventory levels, managers can identify potential issues promptly and mitigate any losses or wastage in terms of quantity or quality.

-

Anomaly Reporting

Human intervention in the production process can sometimes lead to errors. However, IoT devices excel in detecting and reporting anomalies, which eliminates the need for constant human involvement. By alerting and reporting any irregularities, IoT devices enable production managers to take necessary steps to address and rectify the situation.

Key Use Cases of IoT-enabled Smart Manufacturing

With various applications of IoT in smart manufacturing, it is easier to gain a deeper understanding of smart manufacturing.

Here are three use cases of IoT that highlight its value in manufacturing operations.

-

Supply Chain Management and Optimisation

IoT solutions for manufacturers provide businesses with comprehensive visibility, control, and data insights throughout their entire supply chain. By leveraging these capabilities, manufacturers can speed up product and service delivery to the market, reduce costs, and enhance quality. This advantage keeps them ahead of competitors with efficient practices.

Predictive Maintenance/Analytics

IoT empowers manufacturers to anticipate and address potential issues before they occur. Unlike traditional preventive maintenance that relies on routine or time-based approaches, IoT automates and streamlines the maintenance process. These systems can detect arising problems or machinery malfunctions which allows manufacturers to take proactive actions. Predictive analytics enable manufacturers to shift from reactive inquiries such as “What happened?” or “Why did it happen?” to proactive questions like “What will happen?” and “How can we prevent it?”. Such an analytical approach enables a shift from preventive maintenance to predictive maintenance.

-

Asset Tracking and Optimisation

IoT enhances efficiency in managing assets at every stage of the supply chain. Manufacturers gain better visibility into assets through IoT implementation in their factories. Tasks such as asset transfers, disposals, reclassifications, and adjustments can be centrally managed and streamlined in real time which provides improved insights into inventory, quality, and optimisation opportunities in logistics.

These use cases are evident enough to understand that smart manufacturing can be integrated into your organisation. IoT being one core Industry 4.0 solution can be beneficial for evaluating specific factors and needs required by manufacturing operations to be productive and efficient.

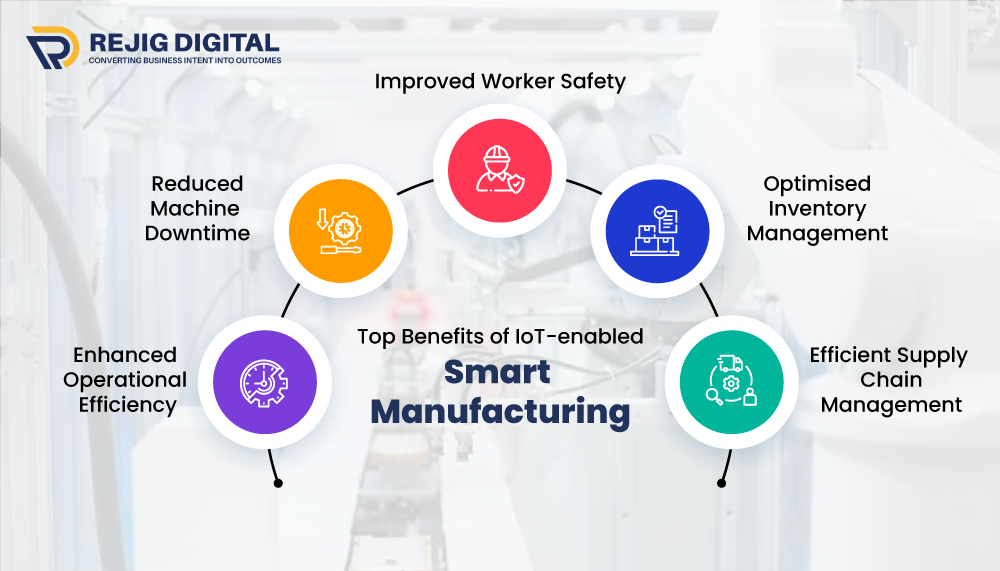

Top Benefits of IoT-enabled Smart Manufacturing

IoT is one of the core digital transformation solutions in manufacturing which has a great impact on industrial operations. Furthermore, smart manufacturing leverages interconnected IoT devices, big data, data analytics, robotics, machine learning, sensor technologies, and artificial intelligence to optimise manufacturing processes, support manufacturers, and ensure worker safety.

However, when it comes to IoT, it has several potential effects on smart manufacturing:

-

Enhanced Operational Efficiency

By gaining real-time insights into each stage of the manufacturing process, plant managers can promptly implement solutions and reduce machine downtime. It results in improved efficiency and cost reduction.

-

Reduced Machine Downtime

Artificial intelligence algorithms utilise operation and failure logs along with real-time data from IoT sensors to provide predictive maintenance insights. It can alert human workers about potential component failures in advance which prevent the escalation of issues into something more serious.

-

Improved Worker Safety

With wearable devices, IoT can facilitate automated tracking and analysis of individuals’ movements and activities within a smart factory to help mitigate risks. Safety systems can alert workers about specific injury risks which identify lapses in focus or errors during tasks, and, if necessary, initiate or request medical assistance.

-

Optimised Inventory Management

Real-time sensor data enables precise tracking of parts and products throughout the manufacturing process. Analytics derived from this data facilitates informed ordering decisions which result in cost savings through consistent scheduling.

-

Efficient Supply Chain Management

Knowing the location of IoT devices allows manufacturers to track shipments, parts, and products within the supply chain. Such information enables adjustments in parts ordering schedules and provides insights that enable products to be easily recycled or reused, hence, reducing the material costs for manufacturers.

Ending Note

Overall, IoT plays a crucial role in smart manufacturing. It simplifies and accelerates production while increasing profitability. In the manufacturing industry, large-scale production does not guarantee profits as it must align with limited demand. Therefore, enhancing efficiency in the production process is the key to boosting profits, and IoT-enabled smart manufacturing is crucial in achieving this goal. Thus, IoT is shaping the concept of smart manufacturing.

Rejig Digital is a leading provider of IoT services with a specialisation in digital transformation solutions in manufacturing industry. With a deep understanding of the challenges faced by manufacturers in today’s rapidly evolving technological landscape, Rejig Digital offers innovative IoT solutions that enable companies to enhance their operations and drive sustainable growth. For more information, get in touch with info@rejigdigital.com.