The Internet of Things (IoT) is revolutionising the landscape of manufacturing with an unprecedented level of connectivity and communication between devices. Manufacturing plants are adopting IoT technology to improve efficiency, reduce costs, and enhance safety. By leveraging the IoT-enabled smart manufacturing plants, industries can achieve greater levels of efficiency, improve data collection and analysis, and optimise system performance.

With the widespread adoption of IoT, it is safe to say that IoT is a transformative element which is reshaping the future of manufacturing.

According to Allied Market Research, The global IoT in manufacturing market size is expected to reach $1,495.65 billion by 2030, with a CAGR of 22.6%.

As we move ahead, we will explore the role of IoT in smart manufacturing plants and the benefits it brings to the industry.

IoT-enabled Smart Manufacturing Plant: A Brief Introduction

IoT technologies enable the collection and analysis of vast amounts of data from every stage of the manufacturing process, allowing plant managers to make informed decisions and optimise production. By deploying sensors and connected devices throughout the plant, IoT provides real-time visibility into the production process, identifying potential issues and reducing downtime.

IoT also enables predictive maintenance, allowing machines to be repaired before they fail, preventing unplanned downtime and reducing maintenance costs. Additionally, IoT can be used to optimise the supply chain, track inventory levels, and reduce waste. Overall, applications of IoT in smart manufacturing are a key enabler in transforming traditional factories into agile, data-driven, and efficient facilities.

Most of IoT’s value for manufacturing comes from its ability to optimise operations.

However, IoT has the potential to transform every aspect of product development and delivery, spanning from the plant floor to the value chain.

- By utilising machine sensors, factories can measure and minimise their energy and water wastage, resulting in reduced expenses and ecologically responsible practices.

- Manufacturers can insert data from other systems and devices directly into the production line. As a result, businesses can achieve improvement in processes rapidly.

- Enhanced asset tracking and sensor-triggered alerts allow manufacturers to initiate orders when their inventory runs low, facilitating a fully automated inventory replenishment process.

- Manufacturers can automatically detect potential equipment malfunctions beforehand which protects their workers and mitigate unplanned downtime.

Top 5 Use Cases of IoT-enabled Smart Manufacturing Plants

The Internet of Things continues to gain traction via various areas of manufacturing plants. Let’s take a look at some of the common use cases of IoT in plant automation.

-

Predictive Maintenance

With IoT sensors collecting data, companies can plan beforehand about the repairing of machines as they will instantly receive notification of asset health at every step of the way. As a result, enterprises can significantly minimise downtime and achieve high productivity in their operations.

-

Supply Chain Automation

A supply chain management system consists of two things- enhanced efficiency of operations and optimal supply of products to meet the growing demand. Both need to be aligned with the requirement of production. Enterprises can gain flexibility in operations so that they can adapt to changing market conditions with IoT automated supply chain.

-

Monitor Building Management Systems

When it comes to large-scale production, it’s crucial that every professional working on the floor has optimum conditions for work. Manufacturing plants have a wide range of things running simultaneously. Things like

factory air conditioning, production speeds, raw material processing, and many more need strict controls to ensure safety and long-term profitability. Integration of IoT in the Building Management System (BMS), heating, ventilation, lighting, and other aspects of the manufacturing factory can be controlled seamlessly.

-

Industrial Robot Process Optimisation

IoT in robot automation is a common practice in many industries. Factory floors and production plants constantly require customisation in this fast-paced transitional market. Optimisation of robots through automation encompasses actuation inspection and changing functions remotely. Companies can achieve the actuation of robots by analysing video recordings of their actions and methods.

-

Remote Error Detection

Most sectors engage customised assets which suit the use case of manufacturing. It requires constant monitoring to ensure that the intended work is correctly implemented. A system that instantly takes note of changes and alerts the concerned team which is important for process stability.

Error detection is one of the crucial use cases of IoT industrial automation as users can quickly detect false alarms and reduce downtime which can have a dire impact on profitability. A remote IoT system also enables teams to notice serious faults in operation and prevent workplace hazards.

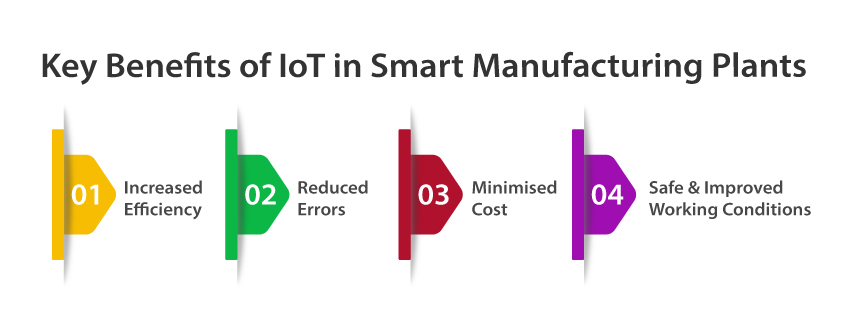

Key Benefits of IoT in Smart Manufacturing Plants

Manufacturing businesses that use IoT in operations can gain greater improvement in a wide range of areas. IoT offers a wide range of advantages to business processes in manufacturing units.

Here are the vital benefits of IoT for the manufacturing sector.

-

Increased Efficiency

The whole connected framework of IoT allows the task to complete at a much higher speed than human workers. It can complete a high amount of work in a much shorter time.

The smart IoT system reduces downtime as unlike human employees, they cannot get tired or take leave. Therefore work can continue even in a reduced capacity. As smart devices are always active, it allows smoother transitions of work from one shift to another.

-

Reduced Errors

The data collected through IoT systems are accurate. Human workers can get tired, misjudge the information or come to false conclusions. IoT systems don’t make such errors and offer accurate results.

Contrary to human workers, IoT systems can process a higher volume of data without taking a break. You can use this high amount of data to achieve improved and more granular analyses of your operation.

-

Minimised Cost

The costs of deploying an IoT smart management system are quickly recovered by reducing the labour and associated staffing costs. These savings will increase with each year as businesses can optimise new processes.

IoT systems help enterprises to excessively reduce losses and inventory shrinkage.

The IoT remote monitoring and management instantly notify supervisors when a machine unexpectedly breakdowns. It allows managers to repair the devices quickly and gives better insight into the asset condition. The managers can take an informed decision before the issue escalates into a bigger problem. Hence, it saves money on constant repairing and decreases asset downtime that contributes to the productivity of the company.

-

Safe and Improved Working Conditions

Automation driven through IoT technology can reduce hazardous and cumbersome tasks for workers. As a result, workplace accidents can reduce which translates into fewer workers’ compensation claims, fewer production delays, and an overall reduction in stress for both workers and management.

Wireless IoT solutions are also useful in locations that are hard to reach for human workers. For instance, deploying cranes or automated guided vehicles is easily controlled through a wireless connection. It is also effective for material handling and process automation in environments where working is unsafe for human workers.

Key Takeaways

Enterprises utilise IoT technology to achieve smart operations by connecting equipment and providing real-time information to workers. Various IoT applications for smart manufacturing plants such as predicting machine maintenance and live monitoring of assets, etc, help industries enhance results and operations for gaining a competitive edge.

Rejig Digital is a leading IoT provider having complete know-how of driving digital transformation with IoT disruption most optimally and cost-effectively. Our goal is to overcome industrial challenges with the right IoT solution for improving the production process.