The Internet of Things (IoT) has rapidly changed the way we live. The world of connected devices has opened a new horizon and increased our productivity multifold. In this blog, we will take a deeper look at the top 5 applications for Industrial IoT and how the Industrial Internet of Things (IIoT) is revolutionizing industrial processes and business operations.

What is the Industrial Internet of Things?

The Industrial Internet of Things (IIoT) is the integration of interconnected sensors in the existing industrial machinery. These sensors optimize the industrial work output and monitor the equipment and its surroundings to constantly transfer the data. The Internet of Things focuses on consumer output and appliances, while the Industrial Internet of Things focuses on tailored-made industrial environments.

How does IIoT work?

The world is running on constant communication and connectivity, similarly, IIoT works on seamless communication between machinery, sensors, and cloud systems. Bluetooth, Wi-Fi, and the internet via cellular network is maintains the connectivity. These sensors collect and exchange data in real-time enabling businesses to make informed decisions.

What is the difference between IoT and IIoT?

IoT involves home appliances and devices that are connected to the internet. These devices mainly provide convenience to users. Internet connectivity gives these appliances the ability to act smart and learn continuously by observing user patterns. While IIoT involves sensors equipped with industrial machinery.

Industrial machinery can be geared into any area such as manufacturing, energy, healthcare, oil & gas, and beyond. These machines continuously learn from the environment and improve their stability, reliability, and scalability. Sensors help these machines to act as an IoT remote assessment tool so they can be used from anywhere, any time.

Which industries are using IIoT?

IIoT is being adopted by every major industry, including IoT solutions for manufacturing, agriculture, pharma, and more. These industrial solutions go beyond optimizing the current workflow processes, they revolutionize the way how business has been operated.

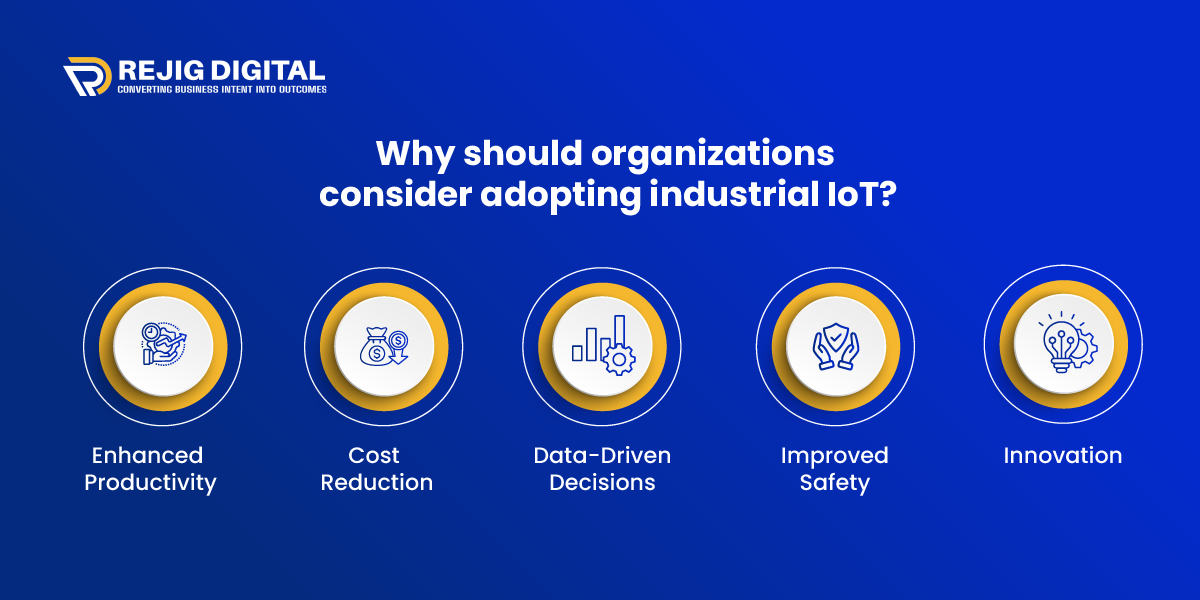

Why should organizations consider adopting industrial IoT?

Adopting Industrial IoT benefits organizations in numerous ways. By leveraging this transformative technology, organizations can learn about their businesses with much more depth and make the right decisions that help them grow.

Enhanced Productivity

Industrial IoT solutions help to enhance the productivity of organizations by providing real-time monitoring. The data gathered from machinery leads to streamlining the processes and reducing downtime. Businesses can identify the inefficiencies and take prompt action to increase productivity.

Cost Reduction

Machines will soon take over the job of men, this phrase has been in use for years. However, now seems to be the time when we are seeing some growth in this direction. Businesses can reduce the cost of their existing production by implementing new solutions that guide them. Predictive maintenance has extended the lifespan of machinery.

Data-Driven Decisions

The abundance of data generated by sensors can help to make informed decisions based on real-time insights. Advanced analytics and machine learning algorithms analyze the vast data and process them to find the right output. They identify patterns, trends, and anomalies and enable predictive analytics for future decision-making.

Improved Safety

IIoT solutions can help maintain and improve the workplace environment. These solutions can help maintain workplace safety. IIoT helps to detect hazardous situations like checking and maintaining air quality, detecting leaks, and preventing them from spreading.

Innovation

IIoT embraces innovation and fosters a culture of adaptability. Connecting devices and using advanced technologies can give birth to new business ideas and models. These methodologies can improve the existing business cycles and give birth to new businesses that are based on top of this technology.

The Top 5 Industrial IoT Applications

Industrial IoT applications have transformed the way machines are connected and analyze data. The data is used to improve efficiency, reduce costs, and enhance safety. Below is the list of top 5 Industrial IoT applications that are imoroving the overall landscape of the industry.

Predictive maintenance

The first of top 5 Industrial IoT applications is predictive maintenance. By using sensors to monitor equipment performance, businesses can predict maintenance whenever required. This can help to prevent costly breakdowns and downtimes of the equipment. Predictive maintenance helps to extend the life expectancy of equipment. Predictive maintenance helps to reduce or eliminate unexpected equipment failures which might cripple the entire production lines.

By catching the problems in earlier stages, companies can avoid higher costs of repairs or equipment failures. It can help to improve efficiency and ensure the equipment is running smoothly.

Inventory Management

Real-time inventory management can help companies avoid stockouts and make the fulfillment and order process simpler. IIoT tracks the shipment and utilize the nearest resources available to it. Traditional inventory management often leads to stockouts or overstocking. Sensors and RFID tags can improve real-time information such as the location, quantity, and status of the product.

Smart Manufacturing and Industry 4.0

IIoT backs the smart manufacturing and paradigms shift towards industry 4.0. Through interconnected data systems and data analytics, businesses can interconnect the systems to keep a watch on every aspect of the IoT in manufacturing. This gives real-time data and eases the path towards troubleshooting.

Remote Monitoring

Remote monitoring helps minimize the intervention in industrial processes. It empowers anyone to manage and operate the system from anywhere on the earth. Connected sensors and actuators along with system controls can help monitor key parameters from anywhere.

Asset Tracking

Asset tracking stands as one of most important factor in the list of top 5 industrial IoT solutions. The IIoT-enabled inventory management can help track assets across the entire supply chain. It can help to track conditions, locations, vehicles, tools, and inventory. This can help to improve logistics and optimize resource allocation.

The Industrial IIoT has begun the journey towards revolutionizing the industrial process, creating a network of machines that helps businesses. The collected data is processed and analyzed thoroughly, which helps to maintain a smooth workflow. IIoT offers groundbreaking applications that keep going to emerge and give a boost to every industry in terms of efficiency and innovation.