Mass adoption of Internet of Things solutions push industries to start to rely on derived data from N number of operations. As a consequence, now businesses are growing based upon data sets and moving forward with a data-proven approach.

By analysing and exploring the capabilities IoT possesses, oil and gas industry innovative thinking focuses on their IoT solutions. Whether it’s about oil and gas business solutions, remote asset monitoring software, or empowering connected assets; IoT is the core choice of oil and gas organisations.

The projected compound annual growth rate (CAGR) of 21.86% from 2019 to 2024 is expected to drive the global IoT services in oil & gas market to reach a market value of $43.48 billion by 2024. (Source)

Key Segment Covered by IoT Powered Oil and Gas Business Solutions

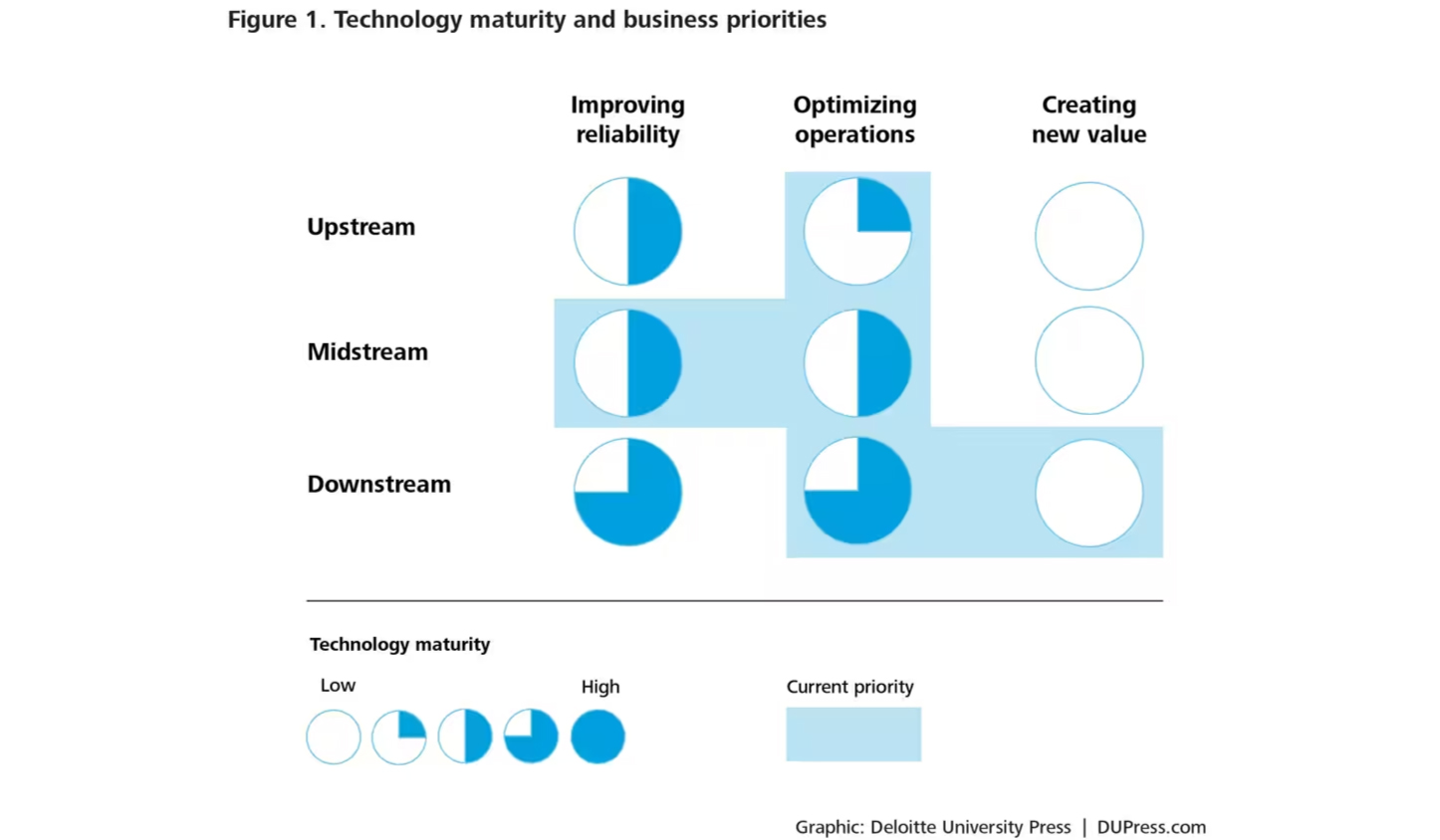

- Upstream Operations: By leveraging the capabilities of IoT solutions, the oil and gas industry can enhance drilling and extraction management, reduce non-productive time, and improve overall operational efficiency.

- Midstream Operations: In midstream operations, IoT is proven as a disruptive technology in the form of asset remote monitoring solutions to improve fleet management, pipeline and storage maintenance, and enhanced supply chain optimization.

- Downstream Operations: Utilise IoT-enabled oil and gas business solutions to streamline the processing and distribution of oil and gas, improving operational effectiveness, reducing costs, and raising customer happiness.

Benefits of IoT-driven Oil and Gas Business Solutions

- IoT-Driven Predictive Maintenance: businesses that come under the oil and gas industry are utilising legacy machinery that are approximately 15 years old. Thus, in the modern era, following reactive machine maintenance processes brings an array of disadvantages. On the other hand, embracing proactive predictive maintenance empowered by IoT technology driven oil and gas business solutions allow businesses to eliminate unplanned downtime and minimise losses caused by production disruptions and other challenges.

- IoT in Energy Management: Employing IoT Energy Management Solutions facilitate effective monitoring and controlling for energy consumption. It offers benefits to the oil and gas businesses to control the usage of energy to reduce wastage, improve energy efficiency and bring sustainability.

- Increase Safety at Field: Oil and gas largely contain field works, thus it’s become prominent to keep eye on workers’ safety aspect. Technology like IoT promises to provide comprehensive worker safety and mitigate potential risk. IoT sensors allow early detection of hazardous situations and timely intervention to prevent accidents or incidents.

- Hazard Management: IoT in oil and gas industry server one major advantage is its ability to prevent gas leakage incidents. Installation of IoT and Connected Assets, Remote Asset Monitoring Software keep update field workers about abnormal situations, monitor gas and energy level, and trigger instant

Implementation of IoT-powered Oil and Gas Business Solutions : Challenges and Resolutions

IoT employment is transforming the oil and gas industry because of its inherent advantages of enabling remote monitoring for better usage of machines, managing energy, optimising production and improving safety factors.

However, the integration of Internet of Things (IoT) in various forms, such as IoT Energy Management Solutions, Remote Asset Monitoring Software, or other types of digital solutions, presents certain challenges. In this section, we will highlight the challenges faced by the oil and gas industry when implementing IoT-powered oil and gas solutions. Additionally, we will discuss potential solutions to overcome these challenges. Let’s begin.

Challenge No 1: Connectivity and Infrastructure

The oil and gas industry often operates remotely through -Remote Asset Monitoring Solutions and harsh environments where they face issues related to connectivity and infrastructure.

Establishing reliable and robust connectivity for IoT devices and enabling IoT and Connected Assets can be a significant challenge, especially in offshore locations or remote oil fields.

Therefore, It requires investing in appropriate communication networks and channels, such as satellite or cellular networks, and ensuring their availability and reliability. Additionally, ensuring that the infrastructure, including sensors, gateways, and data storage, are adequately deployed and maintained is crucial for successful IoT implementation.

- Solution:

To meet this challenge, proper planning and investment in suitable connection alternatives are crucial in the first place. To reduce the amount of data transmission and processing needed, this approach may involve implementing redundant communication networks, utilising mesh networks, or utilising edge computing. Additionally, it is essential to use IoT hardware and infrastructure that is built to survive the challenging environmental conditions seen in the oil and gas sector.

Challenge No 2: Data Security and Privacy

The highly sensitive and essential information pertaining to operations, production, and safety are handled by the oil and gas industry. It is of the utmost importance to ensure the security and privacy of this data.

IoT devices produce enormous volumes of data, which must be securely sent, stored, and processed in order to avoid hacker attacks and unauthorised access. Given the operational complexity of the oil and gas business, protecting data integrity, confidentiality, and availability could prove quite difficult.

- Solution:

To protect data generated by IoT Solutions, it is essential to implement strong data security mechanisms including encryption, authentication, and access restrictions. For the purpose of identifying and reducing any possible cyber dangers, routine monitoring, threat detection, and response systems should also be in place. Additionally, it is important to adhere to all applicable laws, rules, and regulations, including those related to your business, such as the General Data Protection Regulation (GDPR).

Challenge No 3: Scalability and Interoperability

Oil and gas industry executes N number of operations. Whereas IoT in the oil and gas industry involves a vast array of devices and sensors and multiple systems originate interoperability and scalability of IoT implementation.

Therefore, ensuring that every IoT device and sensor communicate and work all together in order to gather more accurate data and help organisations to deliver meaningful insights become crucial to optimise operations. Scalability is also crucial, as the oil and gas industry often involves large-scale operations that require handling massive amounts of data and devices.

- Solution:

In order to confirm interoperability across various systems and devices, IoT implementations can benefit from using open standards and protocols. It’s also crucial to have a modular, adaptable design that supports expansion. The integration of various IoT systems and devices can be made simpler by standardising data formats, APIs, and communication protocols.

Challenge No 4: Skills and Workforce

The oil and gas business needs qualified employees who can develop, install, manage, and maintain complex IoT systems for the IoT to be implemented successfully. Finding talented individuals with knowledge of IoT technology, data analytics, and cybersecurity, however, might be difficult. Additionally, it can require a lot of time, patience, and effort to train existing staff members and adapt to new technology.

- Solution:

Investing in training and upskilling the existing workforce, as well as recruiting skilled personnel with expertise in IoT and related technologies, can help overcome the challenge of skills and workforce. Collaborating with technology partners or service providers with expertise in IoT implementation can also provide valuable support and resources.

Comprehensive Solution: Collaborating with Rejig Digital for IoT Services in the Oil and Gas Industry

Partnering with Rejig Digital to bring modernisation into the oil and gas industry by implementing IoT with zero hurdles and challenges. Rejig Digital, with its years of expertise in IoT and IoT enabled infrastructure allowing oil and gas businesses to go forward with new business models that can help your business to stay ahead in a competitive market.

Consult our tech experts, NOW! Free of cost.